Objective

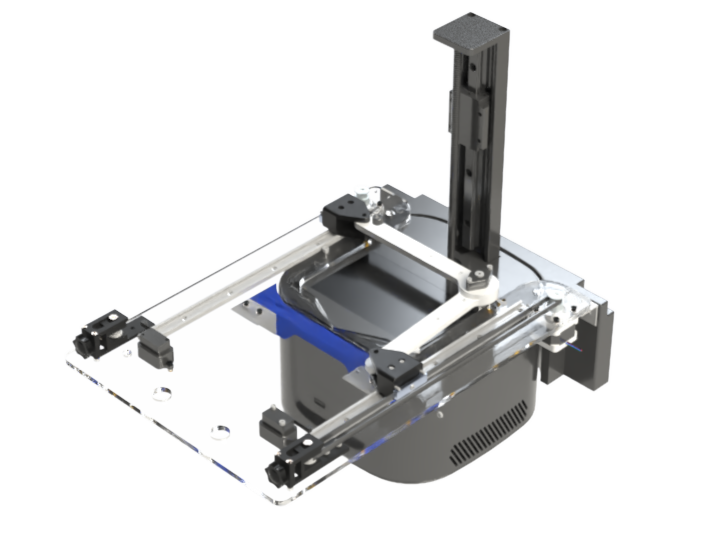

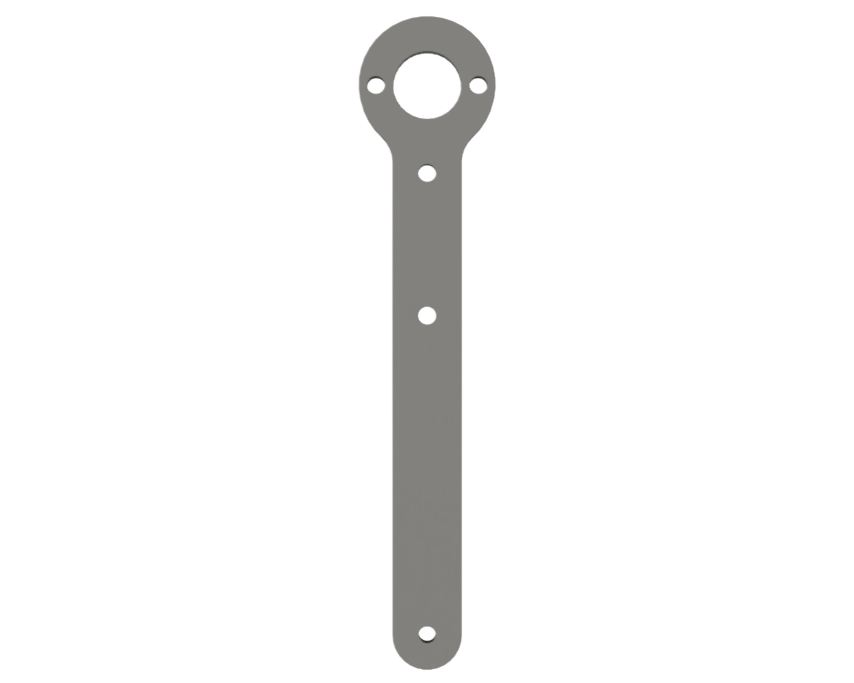

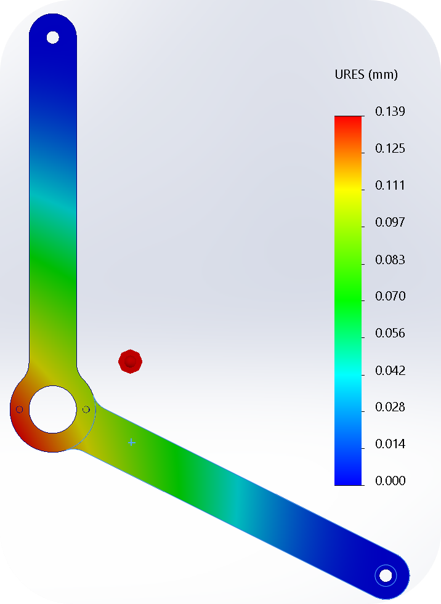

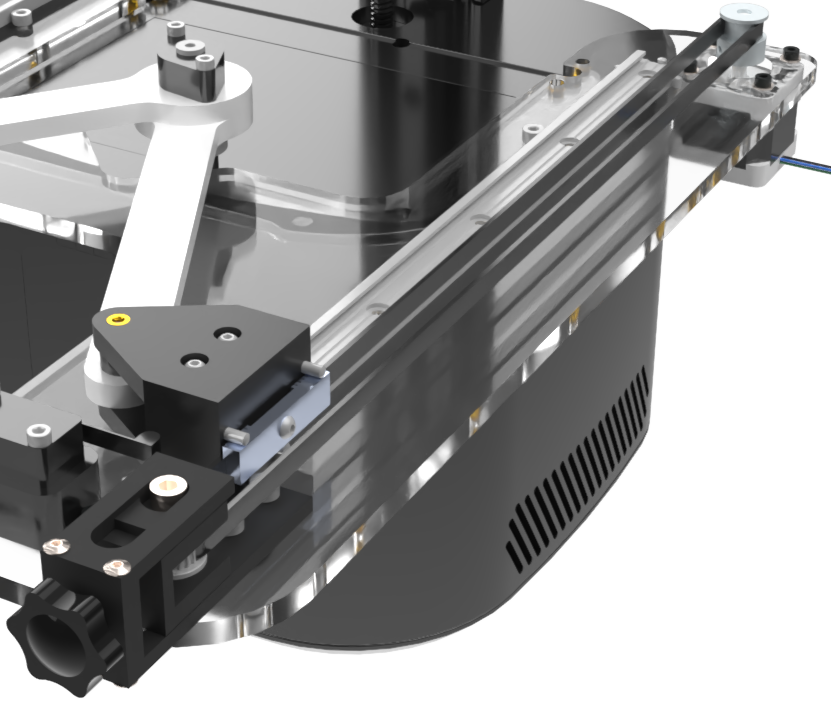

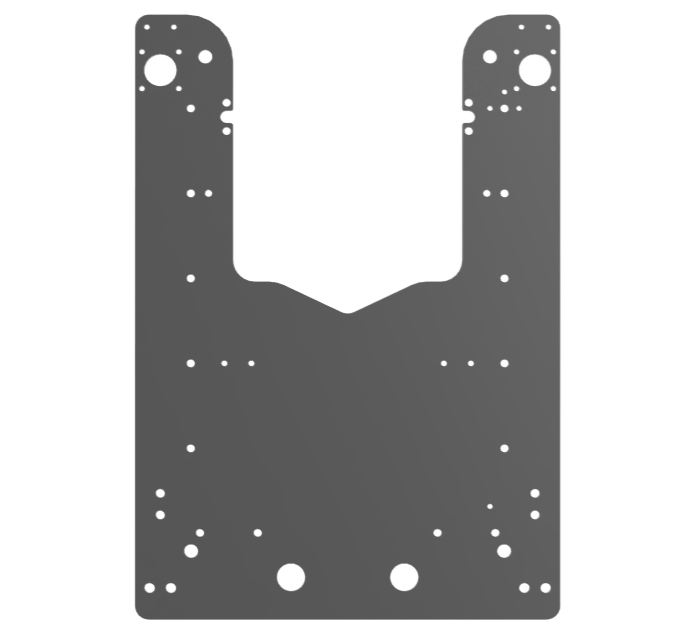

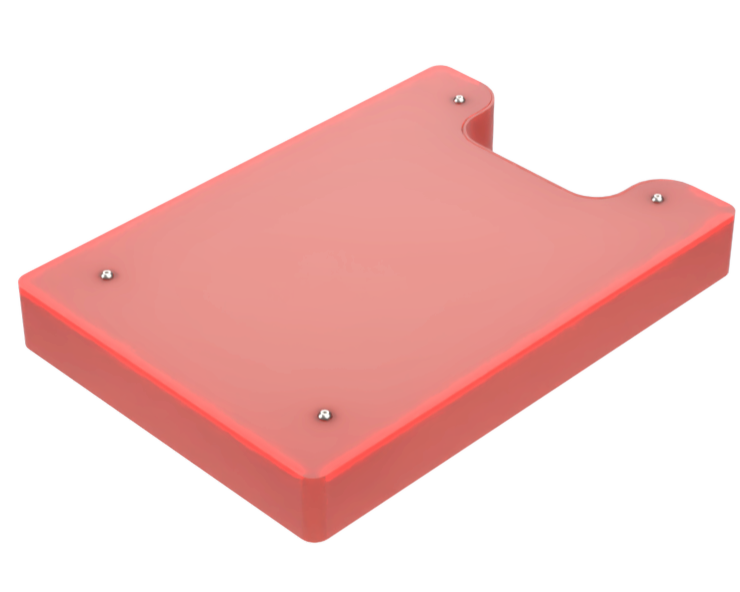

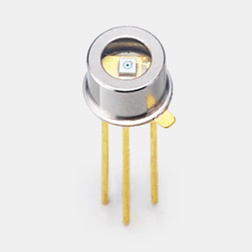

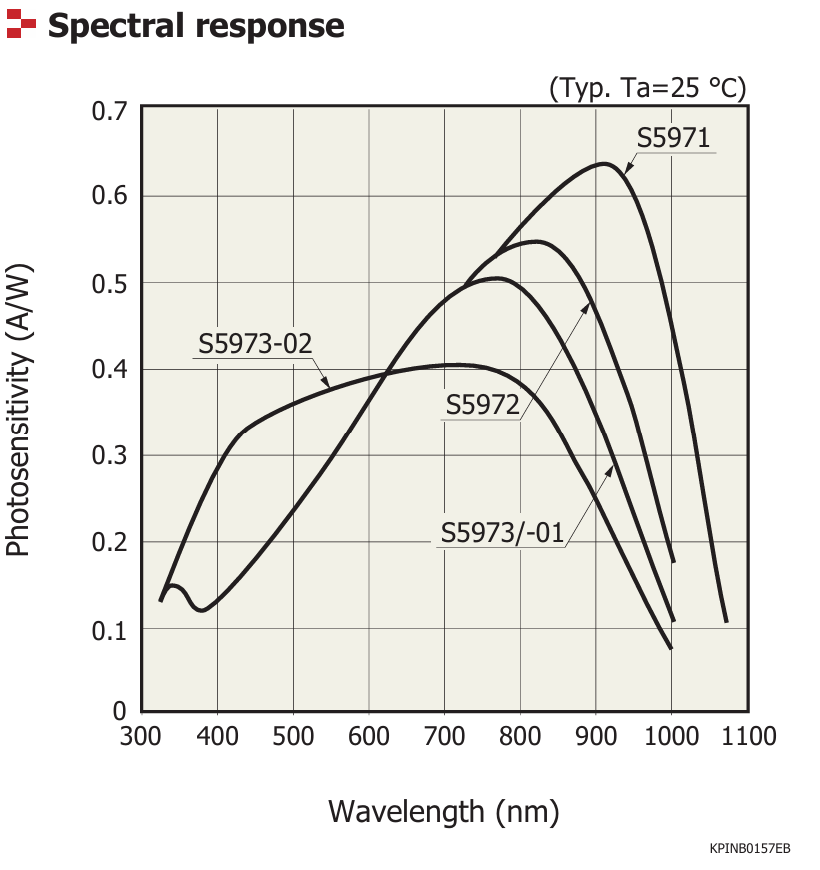

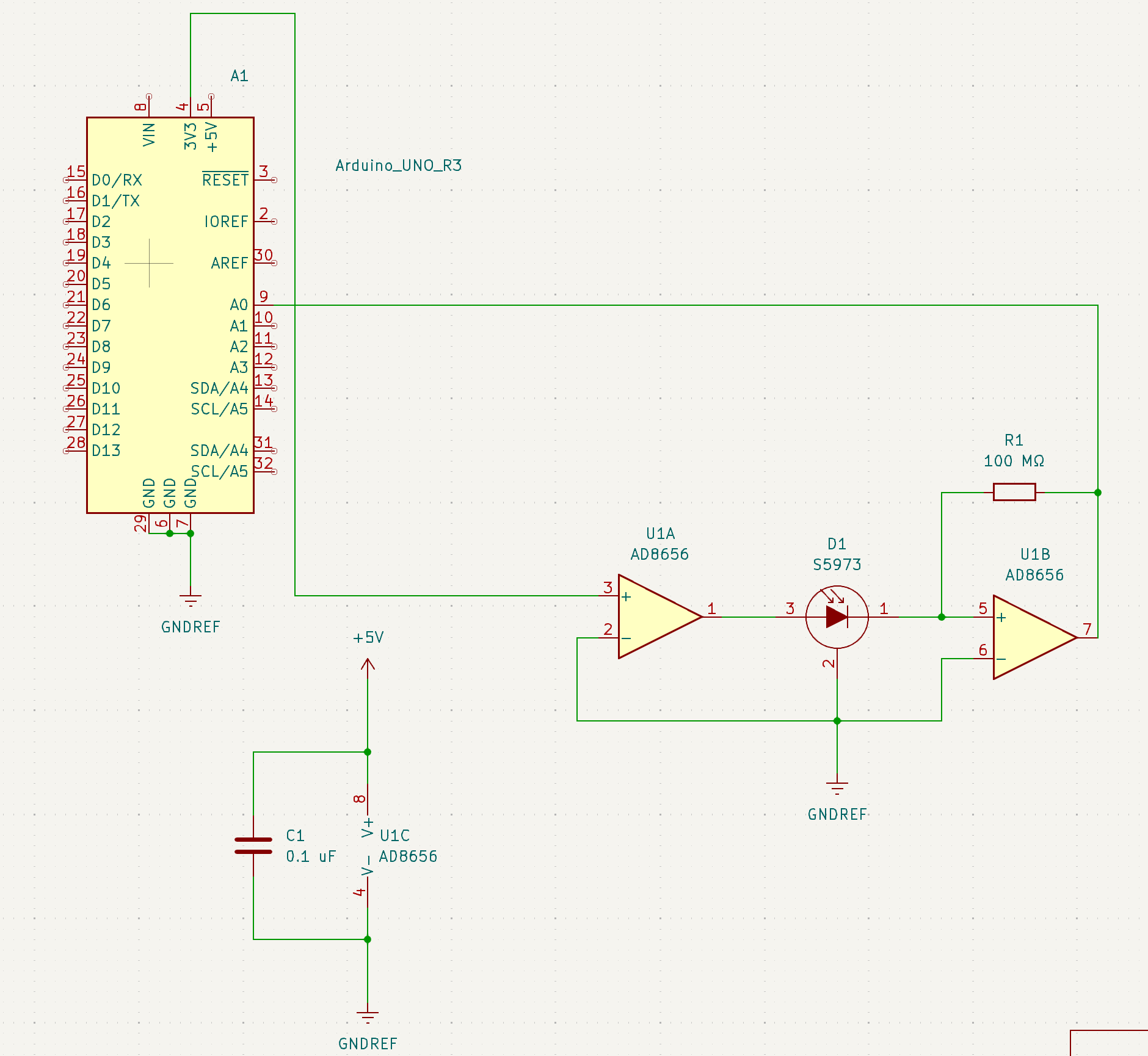

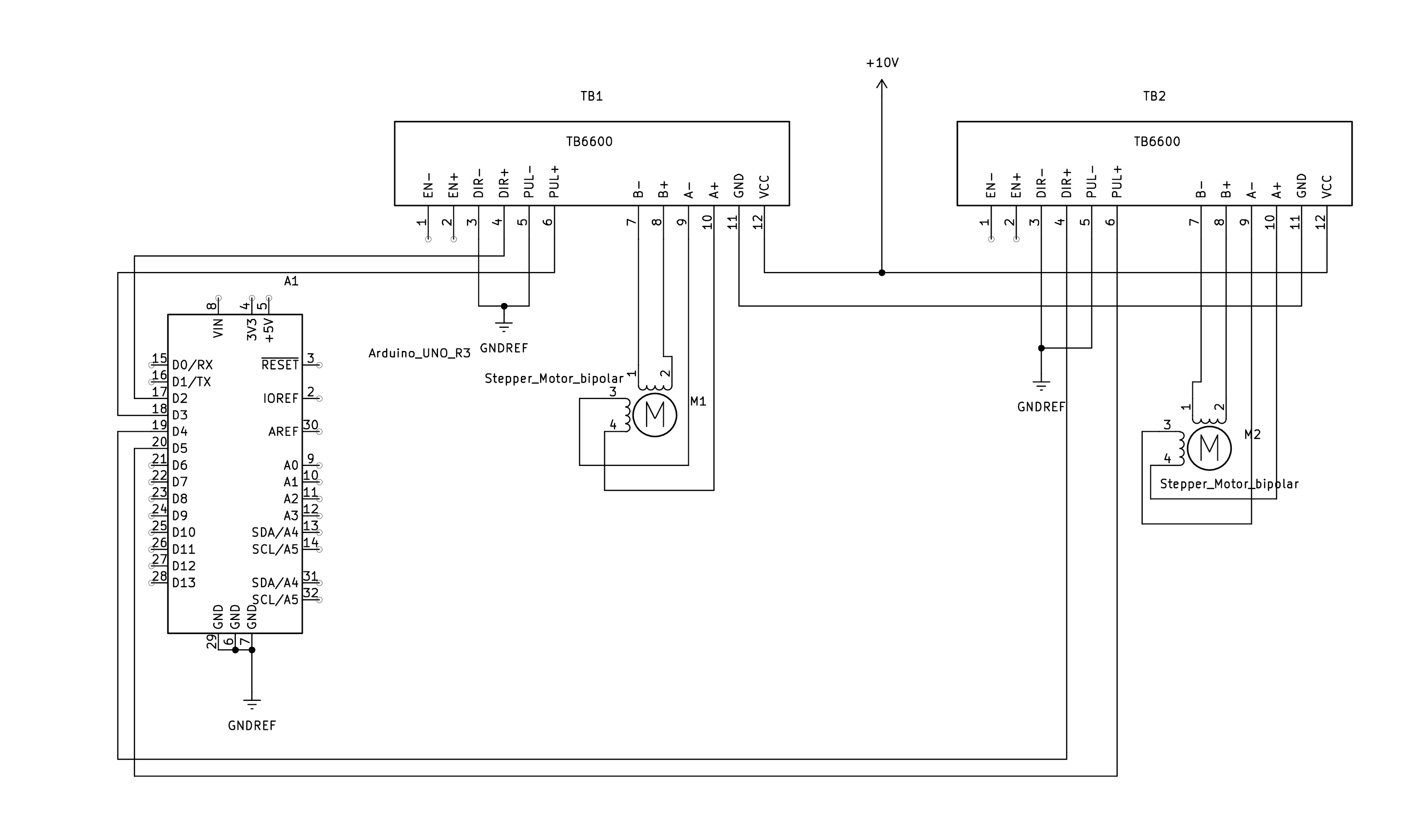

The goal of this Capstone project is to develop a fully automated system for measuring and calibrating the light intensity of a DLP 3D printer. Using a UV light sensor mounted on an automated mechanical fixture, the system will collect light intensity data across various sections of the printer. The gantry will use inverse kinematic arms to move the sensor and collect the data. The data will be processed through a Python script to generate a grayscale image, which will be overlaid with the DLP output to enable precise calibration. This process aims to ensure consistent light distribution and improved printing accuracy.